About 9 or 10 years ago, I read The Anarchist’s Tool Chest, and built a miniature version of one. not long thereafter, I read Campaign Furniture and became very excited about the idea of building a campaign secretary desk.

Look how cool that is! It comes apart into two pieces, there’s a lid to hide your messy work messes, and when the lid is closed, it’s slanted so you can’t stack your junk on it. Genius! I needed one!

So, I set out to build one. I had only vague goals in mind. The most important that It would be able to have two computer monitors on the inside, and the fall front should be about 30″ from the floor. Other than that, I’d pretty much figure it out as I went along. I decided to use pine, because nicer wood is expensive, and I tend to make a lot of mistakes. Plus, this thing is going to be freaking huge and heavy enough as it is, and pine is pretty light.

Anyways, I built about half of the top cabinet, and then I quickly forgot all about the project. The half-made desk sat gathering dust and clogging up my workshop for like 7 years.

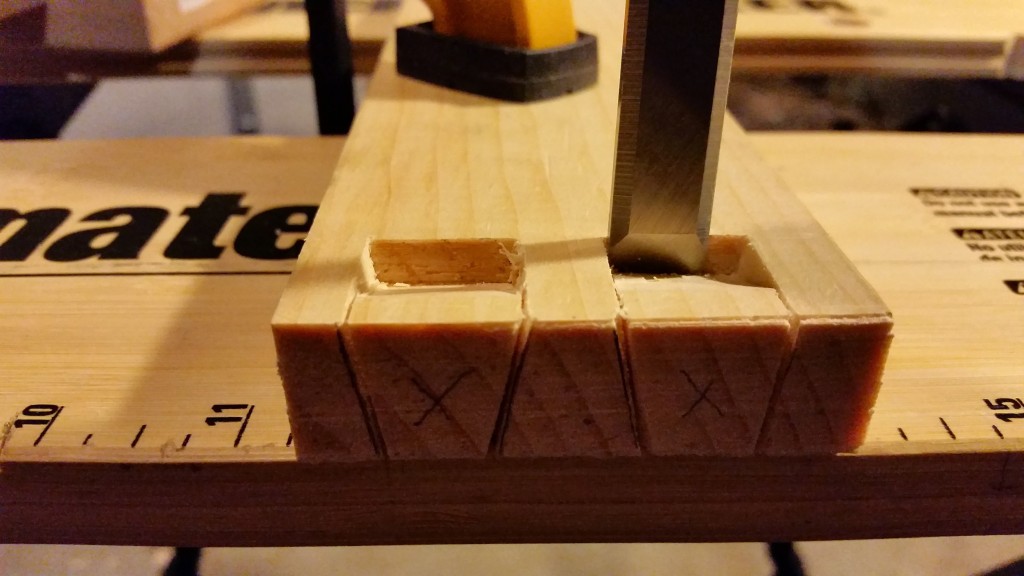

Now, there are other projects I want to get into, but this gigantic half-done desk and its attendant pile of lumber is taking up half of my shop. So, last week, I dusted off my saws and chisels and started cutting dovetails again.

I’m planning to put a couple of hours a week in the shop getting this thing done. Maybe I’ll post pictures and whatnot.